Frequently asked questions about the A250 / A380 automatic coater

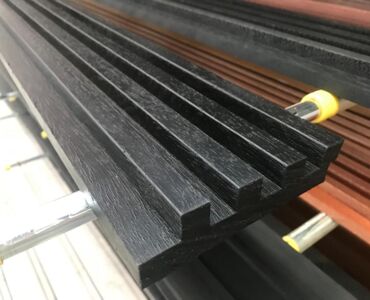

Can the A250 process all colours?

The A250 covers an immensely wide range of colours and glazes. Whether Adler Lignovit Lasur, Remmers HSL 35, KEIM Lignosil Verano, Koch&Schulte Hydrostop H2O... and everything in between: The machine processes almost everything.

Important to know: However, some solvent paints have such a low flash point that there is a certain risk of explosion - which, incidentally, can also be triggered by many other things. We therefore advise against solvent-based paints overall, especially as the market for them is in decline anyway and many ingredients have already been banned, while others have been restricted. Otherwise, there are some hand paints that are so viscous that they simply do not flow well. We would be happy to advise you on a common alternative.

Watch the video: What are the best glazes for you as a carpenter?

Can I handle large projects properly myself?

Firstly, you get ingenious drying trolleys from us, which can hold a lot and can also be moved very easily when loaded. Secondly, the machine is so fast that you can easily paint 1,000m² a day with 2-3 employees. This minimises the time overlap with other work and you simply get it done quickly.

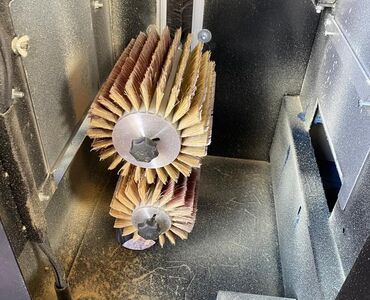

What advantages does the optional sanding module offer?

It extends the service life of the coating because the paint adheres better to the roughened surface than to one that has only been planed. On rough-sawn wood, it removes the loose fibres that would otherwise fall off after coating.

Have a look at our corresponding knowledge article:

Is the A250 also worthwhile for small companies?

Often yes. In many cases, 2-3 wooden façades a year are enough to keep you in the black. How does that happen? Take a look at this video:

Watch the video: How much carpentries save with an automatic painting machine! 💸

I probably don't have enough space - is there a solution?

Mostly yes. Firstly, you can get great and space-saving drying trolleys from us. Secondly, painting is so fast at around 150 m²/h that you can finish it quickly at the end of the day in the same hall that is actually used for other things. In other words, a double use that would otherwise not be possible without a night shift.

Another example: Painting 200 m² of facade, for example, can be completed in two passes on Friday afternoon with two to three people. On Monday, everything is completely dry, so the painting and the rest of the work is staggered and hardly touches each other.

I'm not a painter and have never had a machine like this - is it easy to use?

Don't worry, that's exactly what our customers usually do. To ensure that everything runs perfectly from day 1, you will receive extensive training from us. You'll see: It's much easier than you think. Take a look at our video.

Watch the video: This is how we transport our stringing machines to you!

How much does an A250 / A380 coater cost?

We will be happy to provide you with a customised quote as soon as we know what task you actually have to complete and which machine in which configuration you can actually use best. In addition to your colours and cross-sections, this also depends on how long the amortisation period will be. Spoiler: The machines are so inexpensive that they can often pay for themselves within months.

Watch the video: How much carpentries save with an automatic painting machine! 💸

It's almost always the builders who do the painting - isn't that worthwhile for us?

Most builders don't paint themselves out of passion, but only for price reasons. As many carpenters have already told us, the end result is often so mediocre that carpenters are not proud of their references. If you can now offer 30% cheaper because you have saved 85% yourself, how many clients will say yes to your full-service package? According to our customers' experience, up to 100%!

Watch this video from one of our customers where he describes this change in detail:

Watch the video: Experience with A250 automatic coater - practical report

I've had one of these brushes before, but it was no good, so I'm sceptical, what can you say?

We know these frames well because we have often replaced them. The respective customers quickly realise during the demonstration that this is something completely different. Take a look at YouTube, a customer has or will soon be reporting there.

Who can guarantee that my employees will enjoy using the machine and be able to work well?

Thanks to many years of practical experience, we know how things work. And we pass this knowledge on to your employees as part of personalised delivery and training. It works. And if you have any questions: We can be contacted directly.