Frequently asked questions about the Ceetec DuoFlexSpray painting system

Can the DuoFlexSpray painting system process different types of paint?

Yes, the DuoFlexSpray is designed for a wide range of paints, including water-based and solvent-based products. It offers flexible settings for different paint types and viscosities, ensuring wide applicability for different project requirements.

How quick and easy is it to change the colour of the system?

Thanks to its innovative design and user-friendly interface, changing colours on the DuoFlexSpray is very quick and easy. A colour change can be carried out in just 2-3 minutes, which minimises production interruptions and enables efficient adaptation to different production runs.

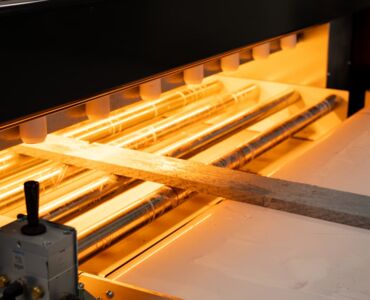

What workpiece sizes can be processed with the DuoFlexSpray?

The DuoFlexSpray can process workpieces with a height of up to 100 mm and a width of up to 1,300 mm. This makes it a versatile solution for a wide range of products, from small mouldings to larger door and furniture parts.

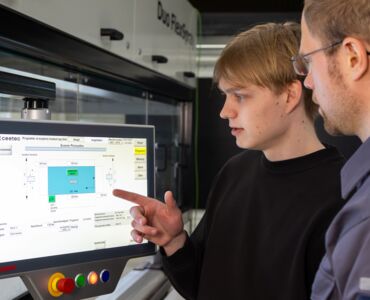

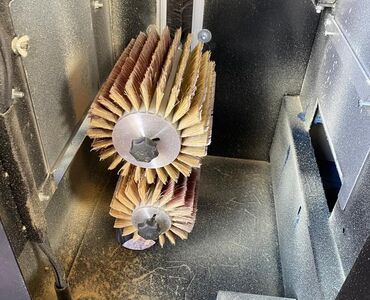

How demanding is the operation and maintenance of the painting system?

Operating the DuoFlexSpray is straightforward thanks to the integrated 19-inch touchscreen and the user-friendly control programme. Maintenance is also simplified thanks to the sophisticated design and easy access to all parts of the machine, allowing regular maintenance work to be carried out quickly and efficiently.

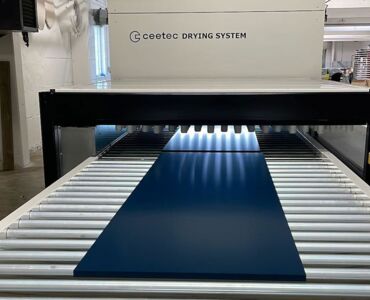

How effective is the painting quality compared to manual processes?

The painting quality of the DuoFlexSpray significantly outperforms manual processes. It ensures an even and precise coating, reduces the risk of irregularities and improves the final quality of the treated surfaces. This is particularly important for companies that value high-quality results and consistent product quality.