Frequently asked questions about the IPM380C automatic coater

How long does it take to clean the machine?

The machine is very openly accessible and is made entirely of PP solid material on the inside. This ensures very short cleaning times of between 15 and 45 minutes, depending on the color. The scope of delivery includes a range of very useful aids that make cleaning much easier. You will also receive personal training to ensure that all the steps are correct.

How much paint do I need to start?

You can start with just 3L! At least if you use the optional spray insert. Using the flood method, you need between 6-10 liters. Good to know: In both cases you can get all but 0.2-0.5 L out again, both systems are easy to rinse.

How long does a color change take?

When using the spray insert, the system is changed after just 3 minutes. Then I may have to rinse or change the brushes. Ideally, we change the shades from light to dark, and if we then stay in the color system, it is basically enough to adjust the brushes by passing them through a “change board” several times. In total around 10-20 minutes, in rare cases and when using the flood box a little longer.

Where is the machine built and where do the electronics come from?

The machine is completely “made in Denmark”, and the electronics come from well-known German manufacturers such as Beckhoff, FESTO and Schneider Electric. So it's a solid machine all round.

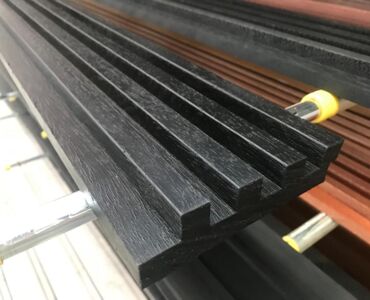

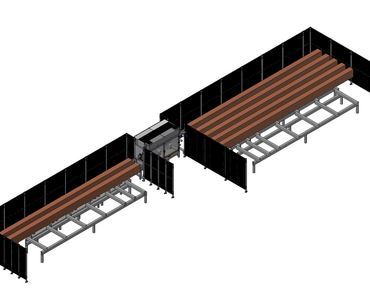

What expansion options are available? Can the machine also produce the black contrast spring?

We have a modular system with over 50 parts that we can use to put together the perfect system for you. Infeed cross conveyors or magazines, grinding machines, dryers, mechanization, stacking - everything you need for efficient production.

Which paints or varnishes can I use - can solvent-based paints also be used?

Yes, you can basically use almost all paint products, even solvent and water-based in the same machine, if we coordinate this well together. Our experts will be happy to advise you personally.

Can I see the machine somewhere?

Yes, either at a customer's premises who is willing to do so, or alternatively at our technical center in Middelfart (Denmark). We are also happy to provide you with samples in advance so that you can see for yourself what is possible.