Frequently asked questions about the P40 automatic coater

How quickly can the P40 be commissioned?

The start time is 5-10 minutes and you're ready to go! To make sure it works just as well for you, we deliver all the machines ourselves and explain to you in detail how everything is optimally operated.

What about cleaning?

Nobody likes washing up after cooking, and fortunately it takes just 20-30 minutes. Again: We'll show you exactly how to do this during the training course.

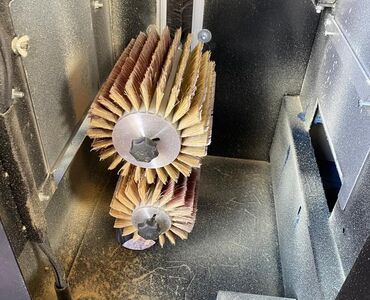

Is maintenance work required?

Almost not at all. As well as being easy to maintain, everything is robust and built to last. The brushes are the same as in our industrial machines and often last for many years in carpentry shops. A care set and a cleaning box are always included so that you can enjoy your machine for many years to come.

Can I use the P40 for small and sporadic jobs?

Yes, the P40 is ideal for smaller projects and is also suitable for sporadic use. Its efficiency and speed make it a valuable addition to any project, regardless of size. If it is not needed for a few months, it can be set up again in just a few minutes.

What about paint consumption?

The amount of paint is adjusted via the brushes and therefore varies. The bottom line is that you save money because nothing goes wrong and only a small amount of approx. 0.2 liters is lost once at the end, everything else stays in the bucket or is applied cleanly to the wood.

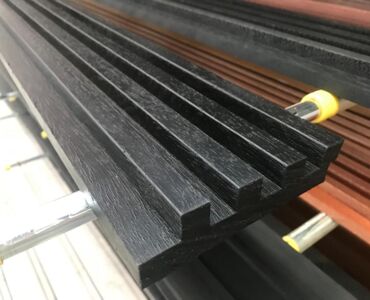

Can I coat different types of wood with the P40?

In principle, the P40 can achieve a beautiful finish on all types of wood. Only with planed larch do all paint manufacturers recommend pre-sanding for better paint adhesion. This is only possible with the larger A250 automatic coater and sanding module.

What happens if I need technical support?

Our customer service is at your disposal! If you have any technical questions or problems, we will be happy to help you so that you can always get the best performance out of your P40.

Watch the video: What is most important when choosing an automatic coater?

How much does a P40 coater cost?

We will be happy to provide you with an individual quote as soon as we know what task you actually have to complete and which machine in which configuration you can actually use best. In addition to your colors and cross-sections, this also depends on how long the amortization period will be. Spoiler: The machines are so inexpensive that they can often pay for themselves within months.

Watch the video: This is how much carpentries save with an automatic painting machine! 💸

I have little space, is there a solution?

Almost always yes. Because: You can paint 200m² of façade, for example, in two passes on Friday afternoon with two to three people. By Monday, everything is completely dry, so the painting and the rest of the work is staggered and hardly touches each other.

It's almost always the builders who paint - isn't that worthwhile for us?

Most builders paint for price reasons. And it's all about the working time, the paint has to be bought anyway. As many carpenters have already told us, the end result often looks so mediocre that carpenters are not proud of their references in the end. If you can now offer 30% cheaper because you have saved 85% yourself, how many clients will say yes to your full-service package?