Coating machines for scaffolding construction

Refurbish your toe boards professionally instead of buying new ones!

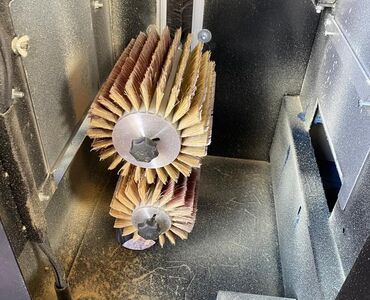

- Sanding and repainting in a single operation - fully automatic!

- Suitable for all standard toe boards and scaffolding planks

- Sand & paint up to 500 toe boards PER HOUR!

- Incl. matching PU paint and screen printing machine for the logo

- Save almost 50% compared to buying new!

Bruhn Streichautomaten has 4,85 out of 5 stars | 23 reviews on ProvenExpert.com

Half the price of buying new

Economical refurbishment instead of manual labour or waste

We set everything up for you on site.

Opaque coating on all sides,

Board by board.

Very easy to operate.

Rework 200 - 500 toe boards/h.

Saves colour,

protects the environment.

Flexible for all toe boards.

Only three steps away

your own painting machine

Step 1: Contact us now

Together we will configure the perfect coating machine that meets your needs and helps you save time and money.

Step 2: See for yourself

Before you buy, we offer you the opportunity to test the machine live on site - with your own toe boards.

Experience how quickly and profitably our machines work and how much working time you will save.

Step 3: Let's get started

We not only supply the coater, but also ensure that everything runs smoothly.

With on-site training and a permanent contact person for you, we ensure that you get the best out of your automatic coater.

Smaller work,

more space for important things.

Impressions

Turning old into new - easier than you thought!

Very easy handling for maximum results - we make sure of that.

- User-friendliness: The very simple operation ensures quick familiarisation - anyone can do it.

- Direct support and training: Our experts train your team on site to ensure optimum utilisation of the machines.

- Suitable for all standard toe boards from Layher or Scafom-Rux, for example.

Our complete range - customised for scaffolding construction

- Necessary accessories included: From cleaning stations to special drying trolleys.

- Optional extensions: Additional modules such as sanding machines for pre-treatment of materials.

- Your smart new logo: We supply the matching screen printing machine.

Does that sound interesting to you?

Then get in touch with us now for a non-binding consultation.

What our customers say

Customer testimonials

"Our colour suppliers from the industry are just as enthusiastic about the machine as we are. The fascination and enthusiasm for your machine has completely spilled over to us and our employees, and they really enjoy working with it. I was sceptical at first, but you have completely won me over."

Kevin Lembcke, Managing Director,

Holzkontor Kuhlenfeld

„Two years ago, we decided to buy a Ceetec P40 and haven't regretted it for a second! Bruhn handled the sale, delivery and initial set-up of the machine competently and reliably.

The delivery of cleaning agents or spare parts, for example, was always handled very quickly. We can only recommend them to others!“

Alexander Kollmeier,

Carpentry Kollmeier

"We had a Ceetec A250 demonstrated to us by Martin Bruhn, and we were so impressed by the demonstration that we would have liked to have welcomed the demonstration machine as a new member of the Lindenschmidt carpentry workshop (unfortunately Martin didn't hand it in)! Martin gave a great demonstration and is always available for questions and colour advice. Keep up the good work, you're great Martin!"

Managing Director / Master Carpenter,

Carpentry Lindenschmidt GmbH

Do you have a painting project coming up soon and want to know how we can support you?

Contact information

Martin Bruhn - Streichautomaten

Krumackerfeld 2

D-24997 Wanderup

Branch office: D-71111 Waldenbuch